HAPPY NEW 2011 EVERYONE

Saturday, January 1, 2011

Wednesday, December 8, 2010

Saturday, November 27, 2010

PULSE ARC WELDS

The top three photos was taken when I just started playing with the pulses on the pulse arc welder. The top left photo is two washers welded together, the middle is two strands from a 12 gauge copper wire welded to a washer and the photo on the right is two strands of a 12 gauge wire that were held against the tungsten electrode while firing a 45ms pulse. The bottom two photos were taken after I managed to manipulate and change the pulses to give better welds. The plasma flame produced here is extremely hot.

I have made thousands of welds and adjustments to get this far and will keep on going until I get it to work perfectly. I accidentally made a plasma cutter that cuts through metal when I made the pulses continuous and also managed to weld a copper wire to aluminum.

I'm limited to the metals I have to do further tests however and will appreciate if someone with knowledge of these welders can help me with some advice. Email me at sprbok@gmail.com

Monday, November 15, 2010

PROCESSOR CONTROLLED PWM RELAY DRIVER SCHEMATIC

When a magnetic solenoid/relay is energized, a magnetic field has to be formed strong enough to pull the plunger in. When this plunger is pulled in, the power can be reduced to a much lower level to keep it in.

This really cool circuit can do the above. If you pull a line, straight down, just before U5 and then build the circuit on the left, you will have a pulse width controlled relay driver circuit that can handle two relays with a total current of 1.5 amps. There are DRV103 IC's that can handle 3 Amps and by changing your power supply to 3 amps, can pull in really big relays/solenoids.

These PWM relay drivers can be activated by supplying 3 to 5V on pin 8 of U2 and U3. The two red LED's will turn on when an over current or over temperature is detected and will shut the IC's down.

This circuit can be changed to drive 12V relays by changing R1 and R2 resistors on the power supply.

When 3 to 5V is supplied to pin 8 of one of the IC's It will turn on fully, supplying 24V to the relay/solenoid and 22milliseconds later (C4 andC5) will start to pulse the voltage at 5000Hz (R3 and R4) and the duty cycle can be changed by adjusting R5 and R6.

R3 and R4 can be changed to get a different frequency, C4 and C5 can be changed if the relay/solenoid needs more time to pull in before a pulsed signal is supplied, just check out the data sheets.

How to adjust:

Put a voltage of 3 to 5V on pin 8 of the DRV103 IC. When the relay pull in, adjust R5 or R6 until the relay fall out. Set it back a little and energize it again to see if it stays in. If the relay doesn't want to pull in at all then replace C4 and/or C5 with bigger capacitors.

THE GERBER FILES FOR THIS BOARD CAN BE DOWNLOADED HERE

Thursday, November 4, 2010

Friday, October 22, 2010

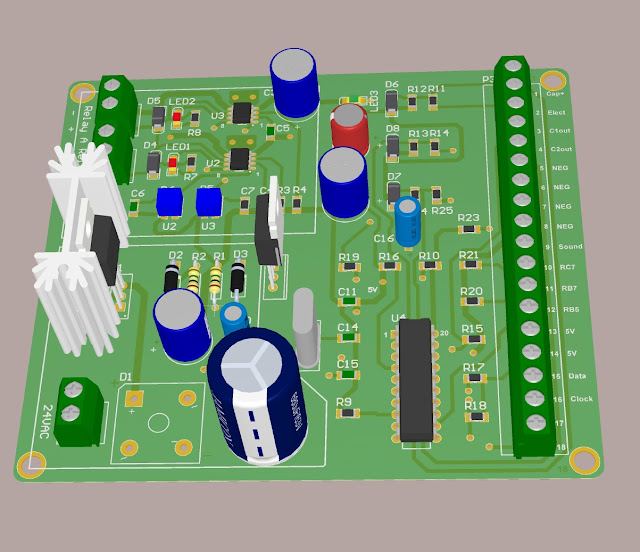

PULSE ARC WELDER PCB BOARD

This is the prototype board, 4 X 4 inches, that will be driving the Argon and electrode solenoids of the pulse arc stylus.

The white block, printed on the board, in the bottom left corner is the 24VDC power supply and the block at the top left corner is the PWM relay drivers. The area on the rights is the microprocessor circuit.

The microprocessor is going to do a lot of things. It will determine if the electrode is touching the work piece, activate the argon solenoid, calculate the time when to give a pulse to the PWM relay driver circuit to retract the electrode, produce a couple of bleeps and give a pulse to start a pulse arc weld.

This processor will also talk to the other processor in the capacitor discharge welder to make energy pulses possible and much much more.

The PWM relay driver will supply 24V to the relay/solenoid and 22Ms (adjustable) later will give a pulsed adjustable duty cycle. This will reduce the current, preventing the solenoids and electronic driving circuits from overheating.

I'm waiting for the components and boards at the moment and will start doing some test welds soon.

This is the prototype board, 4 X 4 inches, that will be driving the Argon and electrode solenoids of the pulse arc stylus.

The white block, printed on the board, in the bottom left corner is the 24VDC power supply and the block at the top left corner is the PWM relay drivers. The area on the rights is the microprocessor circuit.

The microprocessor is going to do a lot of things. It will determine if the electrode is touching the work piece, activate the argon solenoid, calculate the time when to give a pulse to the PWM relay driver circuit to retract the electrode, produce a couple of bleeps and give a pulse to start a pulse arc weld.

This processor will also talk to the other processor in the capacitor discharge welder to make energy pulses possible and much much more.

The PWM relay driver will supply 24V to the relay/solenoid and 22Ms (adjustable) later will give a pulsed adjustable duty cycle. This will reduce the current, preventing the solenoids and electronic driving circuits from overheating.

I'm waiting for the components and boards at the moment and will start doing some test welds soon.

Sunday, September 12, 2010

PULSE ARC WELDING STYLUS

I machined this stylus with my lathe and CNC mill out of aluminum. It compares to the Sunstone Engineering Orion HERE and the PUK 3 pulse arc welders that can weld gold, silver, aluminum, copper, steel, nickel etc. The stylus has a solenoid that retracts the tungsten electrode to start and sustain a very hot plasma arc and argon gas to shield the weld like a TIG welder. This plasma arc is used as a heat source to melt the metal together. Filler rod can also be used to make strong and reliable welding seams.

Saturday, August 7, 2010

A123 UPDATE

These welders have many variables and depending on the size cables, probes and capacitors you used etc. will determine your weld settings. I have done hundreds of welds on A123 batteries and determined that they are no different from any other batteries. When your tabs are too thick to make decent welds, you have to improvise. Current always takes the easiest path and by making dimples and a cut in the middle (picture below) on the tab you are welding will force the current into one dimple, through the battery and out the other dimple. Concentrating the heat on the dimples and produce very strong welds.

You can punch your own dimples and use two pieces of nickel like the picture below.

The probes are also very important, don't use probes with flat tips unless you have a weld head that pushes the probes perfectly flat on the piece that gets welded. Make your tips round on a lathe with a file, like the microscope pictures of my probes below and then use very fine sanding paper to smooth the tips. Rounded tips will make perfect welds every time, won't stick and you can hold the probes at almost any angle.

You can punch your own dimples and use two pieces of nickel like the picture below.

The probes are also very important, don't use probes with flat tips unless you have a weld head that pushes the probes perfectly flat on the piece that gets welded. Make your tips round on a lathe with a file, like the microscope pictures of my probes below and then use very fine sanding paper to smooth the tips. Rounded tips will make perfect welds every time, won't stick and you can hold the probes at almost any angle.

Sunday, July 25, 2010

PULSE ARC WELDING

I'm looking into adding pulse arc welding to this welder. Pulse arc welding is like TIG welding. By adding Argon gas through a special gun with a tungsten tip will produce a very hot plasma arc that will melt almost any metals together( including aluminum, gold and silver). This welder was originally designed to use a contactor and can easily be converted to activate an argon gas solenoid and a retractable tungsten tip. I will appreciate any input.

Saturday, July 3, 2010

ESR TEST AND A123 CELLS

I have measured the ESR of my welder and its much lower than anticipated. The ESR of the welder bus bars at the front of the welder measures less than 0.0005 Ohm (500 micro Ohm). With such low resistance, this welder can produce astronomical currents and will only be limited by the resistance of the probe, wire and material being welded.

I am way behind schedule with my version 3 processor and spent most of my time getting the new welder built.

Most companies and people out there that are welding A123's are very tight lipped about how they do it and I would like to get to the bottom of it!!! I'm doing some experiments with inverted resistance welding and was wondering if there are some of you guys that would send me some of your old A123's to play with ??? I will post all my findings on here!!!

I am way behind schedule with my version 3 processor and spent most of my time getting the new welder built.

Most companies and people out there that are welding A123's are very tight lipped about how they do it and I would like to get to the bottom of it!!! I'm doing some experiments with inverted resistance welding and was wondering if there are some of you guys that would send me some of your old A123's to play with ??? I will post all my findings on here!!!

Wednesday, June 23, 2010

NEW WELDER

I started my new welder up today and did a couple of test welds. The welds look really good and much better than my previous welder. I welded some copper to a washer at very low voltages and also checked to see how fine the settings can go by welding 80 micron gold plated tungsten wire to a washer (the photo below was taken with my microscope) and I placed a small BC 847 surface mount transistor next to it. My probe tips are all messed up and I am busy cutting new ones with my lathe which will make much better looking welds. I will also test the ESR this weekend and I'm hoping that it will be in the 0.001 to 0.0015 Ohm range.

Subscribe to:

Posts (Atom)