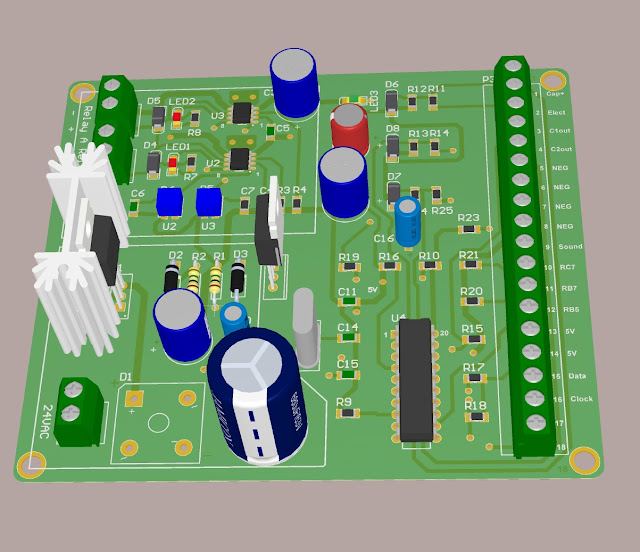

PULSE ARC WELDER PCB BOARD

This is the prototype board, 4 X 4 inches, that will be driving the Argon and electrode solenoids of the pulse arc stylus.

The white block, printed on the board, in the bottom left corner is the 24VDC power supply and the block at the top left corner is the PWM relay drivers. The area on the rights is the microprocessor circuit.

The microprocessor is going to do a lot of things. It will determine if the electrode is touching the work piece, activate the argon solenoid, calculate the time when to give a pulse to the PWM relay driver circuit to retract the electrode, produce a couple of bleeps and give a pulse to start a pulse arc weld.

This processor will also talk to the other processor in the capacitor discharge welder to make energy pulses possible and much much more.

The PWM relay driver will supply 24V to the relay/solenoid and 22Ms (adjustable) later will give a pulsed adjustable duty cycle. This will reduce the current, preventing the solenoids and electronic driving circuits from overheating.

I'm waiting for the components and boards at the moment and will start doing some test welds soon.

Hi fritz would like to know where I can get detailed info to build this spot welder? Where to get schematics,layouts and processor code or where to purchase the following and also the current prices?

ReplyDeleteI have been looking through the Blog but could not find the info? Please help want to build this welder.

Hobbymann, all the boards are sold out, I'm working on a downloadable package so please be patient.

ReplyDeleteHi Fritz, here and on your youtube video you use "Ms". I'm not sure,but I gues it intends to be a time unit milliseconds. If that is the case it ought to be written as "ms".

ReplyDelete"Ms" is MegaSeconds, which makes no sense here.

Another question, what are you using for switching the circuit? in the video I see a large bank of mosfets, I guess, but above you mention a relay and a "argon selenoid". Can you explain what you mean by that? What kind of contacts does the relay have so that they aren't welded shut too.

Ms on here means milliseconds. I'll make sure not to capitalize the "m" in the future.

ReplyDeleteI use mosfets to switch the circuit. The argon solenoid as mentioned above is a totally different project or more like an add on to the current welder. It is a stylus with a solenoid inside(below)that will be connected to the current welder to do pulse arc welding.It will use argon to shield the weld against contaminants. Pulse arc welding is like TIG welding and uses a plasma flame to weld all kinds of metal.

Ditto with Hobbyman's request. I want to join the builders que. My possible limitations may be compiling and loading code for the CPU and getting or making PCBs to mount the components. Is assembly still possible with very good circuit, electronic and soldering skills?

ReplyDeleteYes, assembly is still possible. Its usually when there is a problem that people gets stuck and don't know how to fix it. I am busy, with the help of a friend, designing a new website that will be easier to navigate and make all the limitations this blog have better.

ReplyDeletePlease be patient, I'm almost ready for a test run on the pulse arc welder and then I might, depending on how many guys are interested, have more PCB's made.

It possible to send me both PCB board with all components in Europe,Bosnia???

ReplyDelete